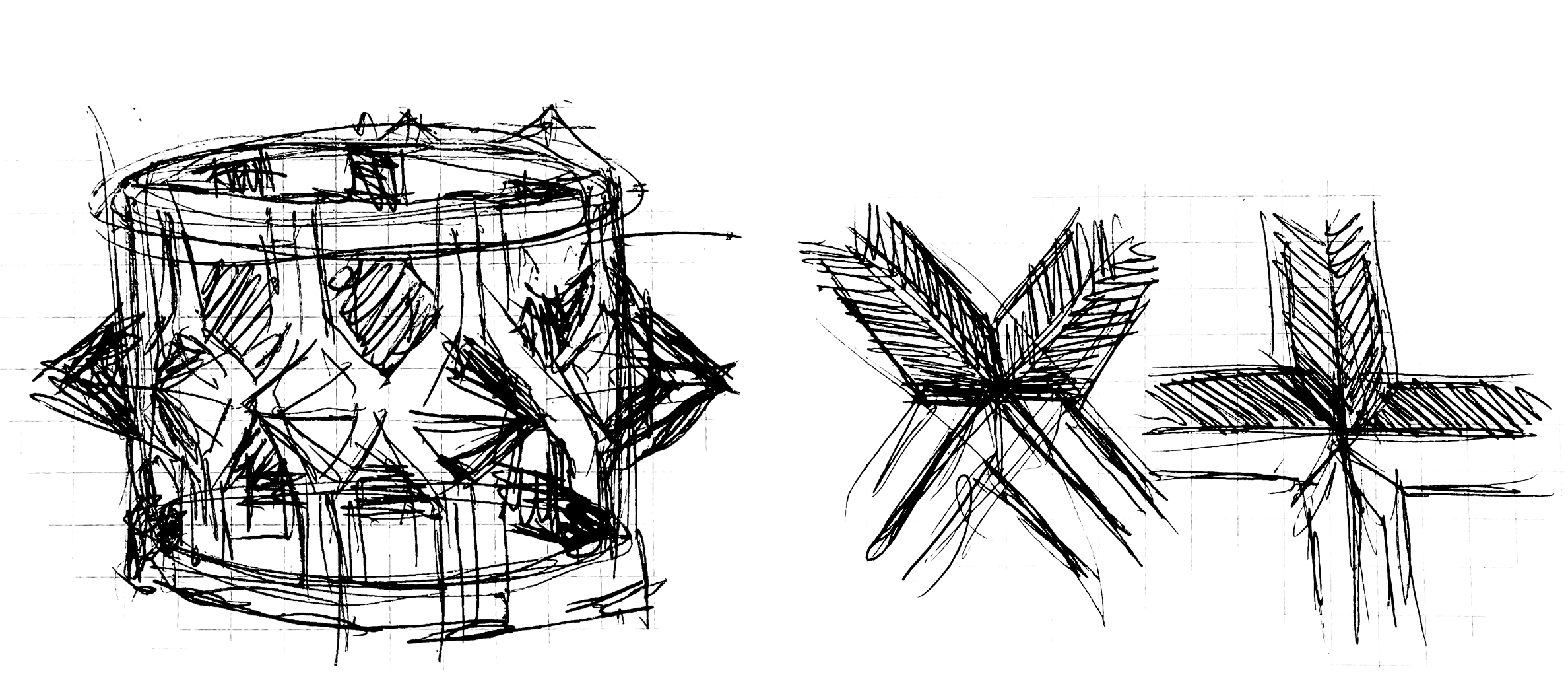

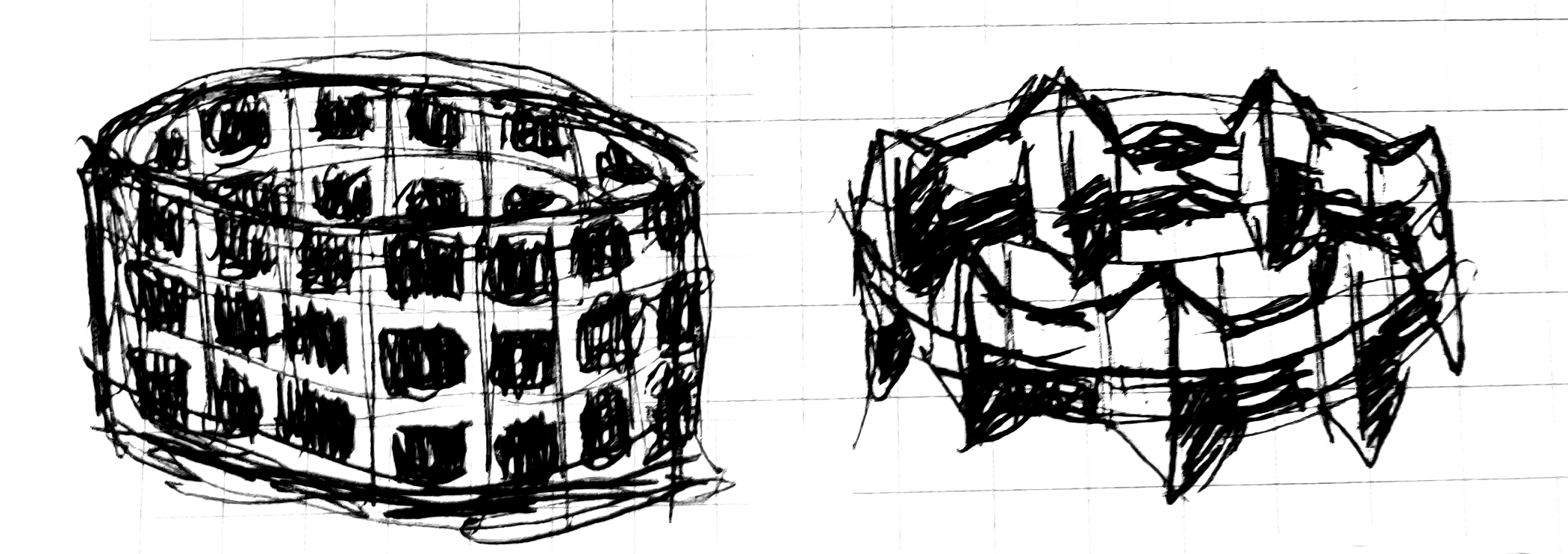

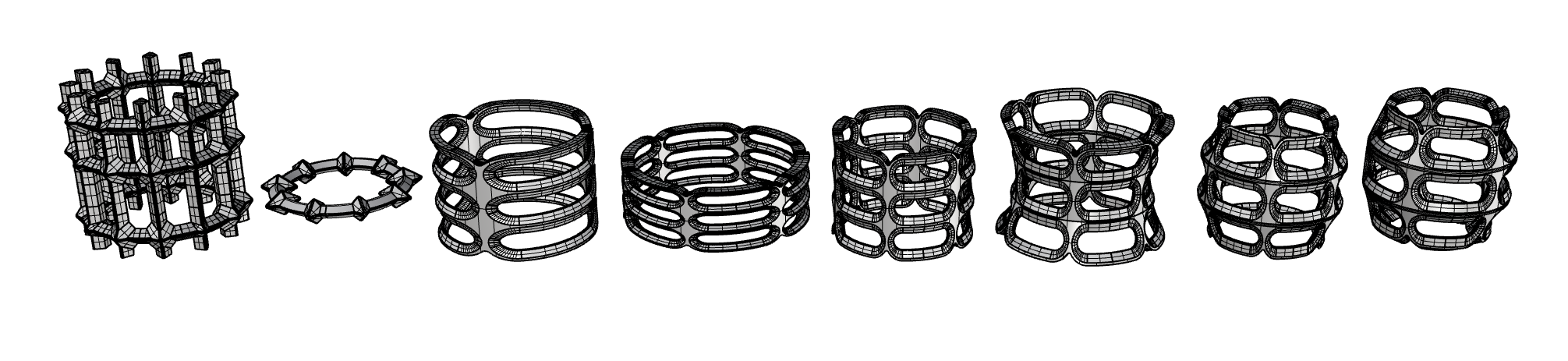

Experimental Design

Creation through intuition

For this project, I aimed to establish a framework where specific variables are strictly controlled while others are left to chance. To achieve this, the project involved casting a bronze frame to serve as a restrictive vessel for blown glass, forcing a physical interaction between the two materials.